13 associate companies have received NADCAP accreditation

Safety and reliability are mandatory in the Aerospace sector. Aircraft manufacture demands a rigid validation process, from parts fabrication to final fuselage assembly.

Validation processes are essential to guarantee aircraft quality and to avoid future problems, once, in aviation sector, any non-conformity in the process may be fatal.

The National Aerospace and Defense Contractors Accreditation Program (NADCAP) is a processes’ approval demanded by the Aerospace industry in the whole world, to improve quality and to reduce production costs, keeping the excellence levels in Aerospace and Defense sectors. Major customers of the supply chain, like Embraer, Boeing and Airbus demand this label for different processes.

Rodrigo Salgado de Azevedo, Embraer Quality Vice President, stated that NADCAP Program is the best way to continuously monitor special processes’ progress, once they are essential to product quality. “Companies accredited by NADCAP are audited in a standard way by technology experts, what motivates continuous improvement processes’ relevant controls, generating world class quality. Embraer acknowledges NADCAP accreditation as a competitive differential in the search of excellence”, as per Salgado’s words.

The Performance Review Institute, PRI, with headquarters in the USA, is responsible for NADCAP accreditation process and holds a database of companies already accredited for consultation. This works as a suppliers’ showcase; main aeronautical manufacturers consult it. “NADCAP Program is a unique approach and is managed by industry for conformity evaluation, it gathers industry and government experts in order to define operational program requirements, to establish accreditation parameters and to certify suppliers”, says Jim Lewis, PRI Nadcap Program Senior Manager.

Always with strategic initiatives to improve its associate companies’ competitiveness, Brazilian AeroSpace Cluster, managed by Parque Tecnológico São José dos Campos, has created in April 2018, the NADCAP Accreditation Program to the associate companies be trained, improve skills, and follow guidelines towards accreditation.

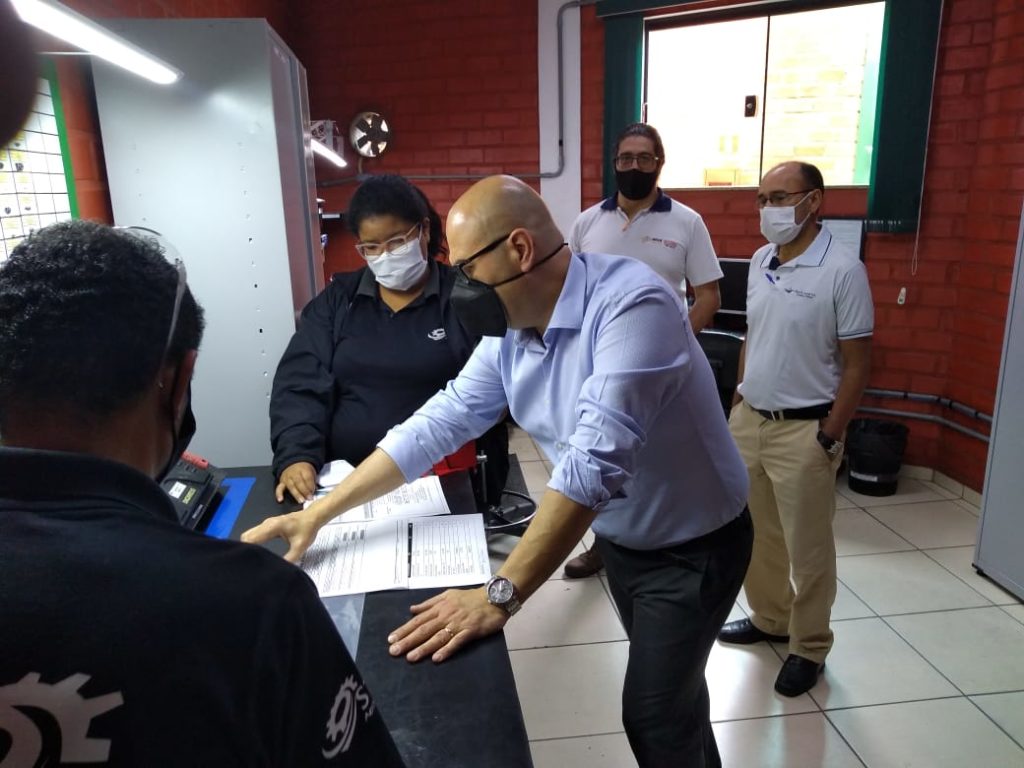

Winnstal company being audited for Nadcap certification

The Program Phase I, still in 2018, has provided optimization of companies’ resources, since some capabilities, trainings and consultancies were performed in group, under the Cluster’s coordination. Phase II was offered in partnership with Apex-Brasil, to improve the Brazilian Aerospace sector international competitiveness. Costs were completely subsidized by Apex- Brasil and, as counterpart, companies were responsible to be accredited.

Pionner Methodology

With a global pioneer methodology, the NADCAP Accreditation Program, developed by the Cluster, highlights Brazil in the market. “There is no report of other similar NADCAP program performed in such a way, nor in Latin America, not even in other continents”, says José Carlos Nogueira, Director of South America Consultoria, Parque Tecnologico’s partner hired to follow the accreditation processes together with the participant companies. “The Program has placed the participant companies among the twenty companies in the world to receive ASA – Aircraft Structure Assembly – commodity NADCAP accreditation, in a total forecast of 900 companies in the world, as per PRI information”, Nogueira adds.

NADCAP Program has taken place in two phases. Phase I focused on Chemical Processes, NDT, Composites and Sealing (considering only AC7135/4 checklist). Phase II Program was specific to ASA Commodity, adding three documents besides AC1735/4). Since the beginning of the Program, 13 companies were certified: Aerocris, Alltec, GMP Marcatto, Inbra Aerospace, Pan- metal, Magnaghi, Serco, STB Aero, Tecplas, UFT, Vemax, WF Estruturas and Winnstal.

Pan-Metal company team – one of the Nadcap certified companies

With the positive results achieved in the certification processes, Brazilian AeroSpace Cluster’s NADCAP Program has become a PRI international case. “The accreditation of a nine-company group was of extreme importance to show that Brazilian productive chain is ahead many other countries in the aerospace deliveries’ quality and customer service”, evaluates Marcelo Nunes, Parque Tecnológico São José dos Campos Managing Director.

PRI remarks the benefits of the program for the market and accredited companies: “Certified companies are benefited from a standard approach to quality guarantee and redundant audits reduction. Parque Tecnológico São José dos Campos’ and Brazilian AeroSpace Cluster’s initiative has then provided these suppliers to become part of a global acknowledged Program”, comments Jim Lewis.

Cases

With NADCAP Accreditation, companies can register and be qualified to assemble mechanical components and structures of major players as Airbus, Boeing, Latécoère, Aernnova, Spirit, Alestis, among others, besides having their competitiveness reinforced with assembly processes standardization, non-conformity index decrease, labor force capability improvement and the possibility to increase their portfolio.

Grupo Serco is one of the accredited companies. For Marcelo Moreira de Assis, its Director President, the partnership created with Brazilian AeroSpace Cluster was of high importance for all the region’s aeronautical chain. “Companies able to follow the Program are nowadays in a huge level of improvement. When we started with our first commodity – Chemical Process, Painting – we’ve realized we were able to apply the concept to all other processes in the company. And that is what we’ve done”, explain Assis. Grupo Serco was also accredited in assembly and is in the process of Thermal Treatment NADCAP accreditation. “We recognize our progress and maturity in all the processes.”, he states.

Assemblers’ demands for certification have left many suppliers lost in the first moment. This is the reason why the methodology and program development, as the one of the Brazilian AeroSpace Cluster, was fundamental for adaptations and conquer of the label.

STB Aero going through the audit process

This is the case of Aerocris. “When Embraer mentioned the need for suppliers to improve their processes with NADCAP accreditation, we had no idea of how to structure and start the project”, remembers Dario Cristaldo, the company director. “Brazilian AeroSpace Cluster’s initiative to lead this Project, enabling and conducting the companies, was fundamental for everyone to efficiently achieve the proposed objective”, he continues. In Cristaldo’s opinion, besides the commercial benefit, the adaptations made to be accredited generated a substantial improvement in the process quality. We can use them as a standard to replicate to other processes, strengthening the whole company.”

COVID-19 pandemic was not Strong enough to interrupt consultancy program and processes. VEMAX, with headquarters in Botucatu, is one of the examples of companies which have reached the certification during the restrictions period. The company has counted on the support of the team indicated by the Brazilian AeroSpace Cluster. “The help given to us was fundamental to interpret periodical diagnosis of the regulatory requirements’ attendance.

Despite all the unexpected events caused by the pandemic we’ve lived, the Project was concluded thanks to team’s dedication and determination, and it was evaluated and certified by Embraer, certified by AS9100 and recently, accredited by NADCAP Program”, says Marcus Vinícius Costa de Abreu.

Record Time

The structure created by the Brazilian AeroSpace Cluster’s NADCAP Program has placed the associate companies within an international aeronautical attendance standard. José Carlos Nogueira states that, when the Program was started, there were fewer than ten accredited companies in the world. The methodology created by the Cluster has helped to optimize the companies’ resources and time, because it has provided workshops, individual consultancies, guidelines to production adjustments, among other initiatives focused on accreditation. In this way, even with recently developed processes, and limited time, accreditations took place successfully.

Another overcome challenge was the deadline established by the Program for adjustments cycles and accreditation to happen: 12 months in total. In a general view, any commodity has the PRI recommendation of, at least, a 24-month-preparation period. “We have succeeded on preparing and accrediting the participant companies in the Project in the established period of 12 months”, celebrates Nogueira.